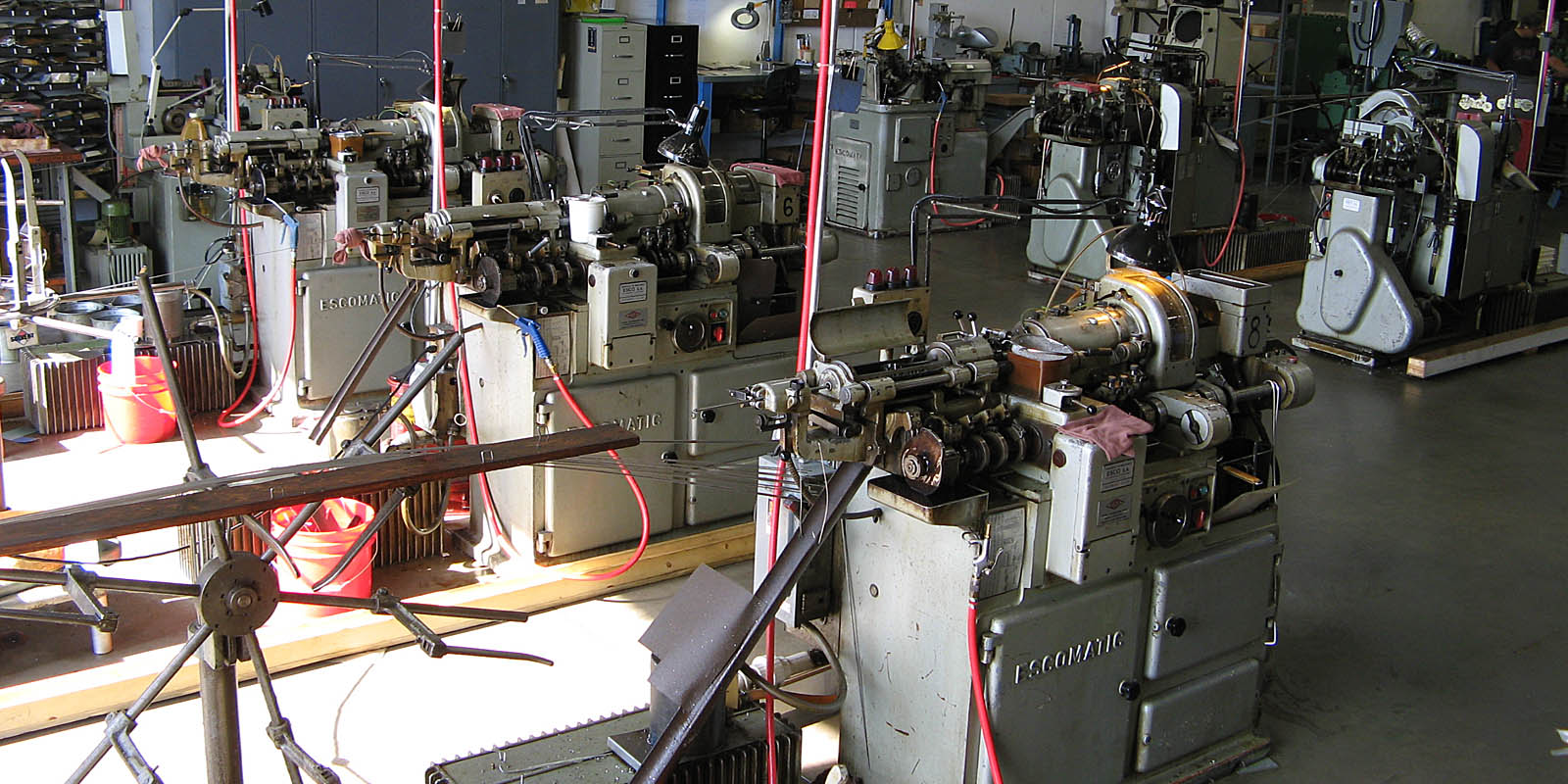

ESCOMATIC WIRE & BAR FEED SCREW MACHINING

MINIATURE PARTS TO 1/4″ DIAMETER WITH BURR-FREE FINISHES…

Models include D2, D4 and D6 Escomatics. Northwest Swiss-Matic can handle your component needs from medium to large volume production including part finishing and assembly.

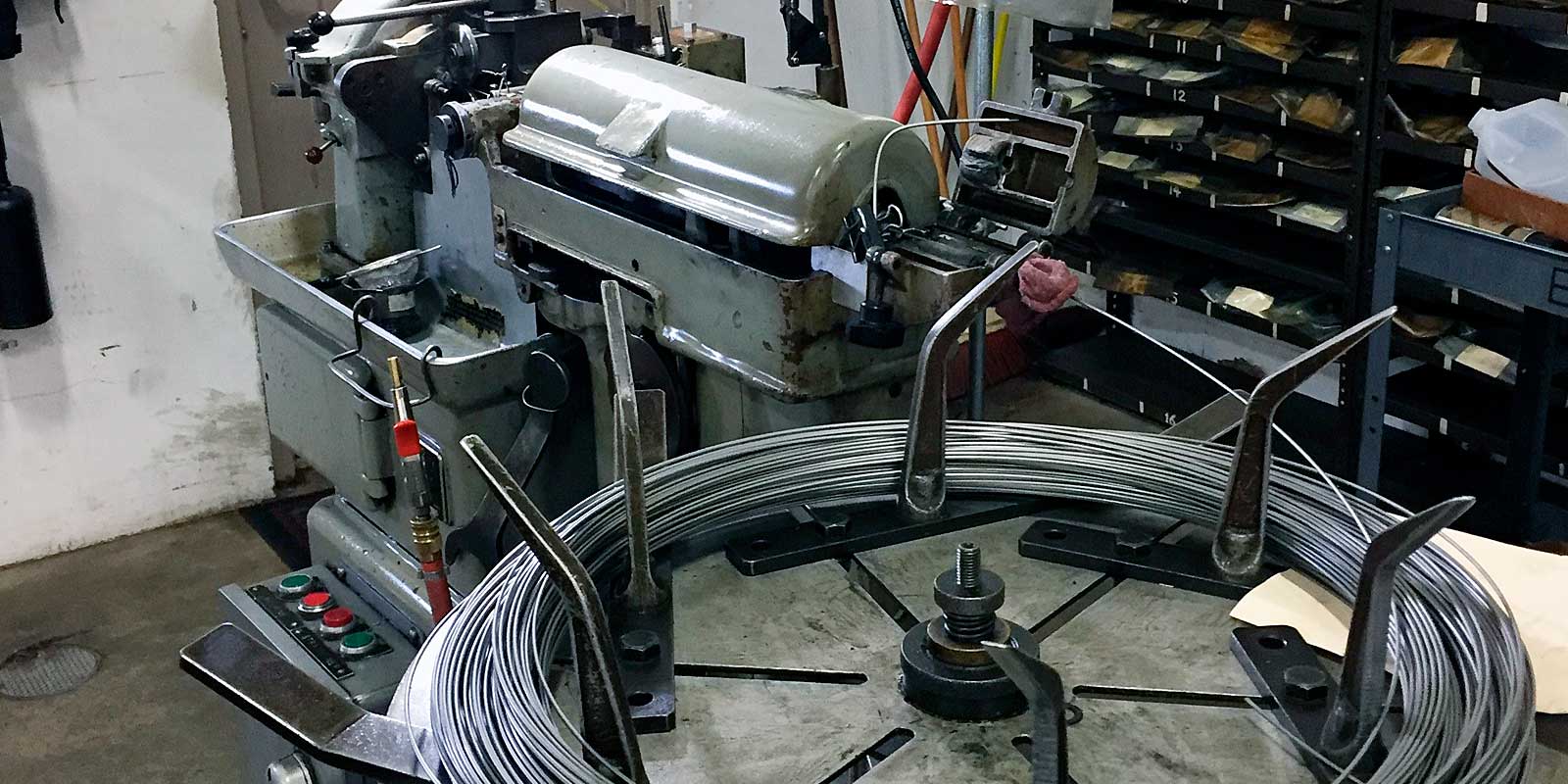

Escomatics Deliver Results. Our wire feed machining systems produce over 100,000 parts per day. Part diameters range from .010″ up to 1/4″ with lengths up to 3-1/2″. Parts are burr-free and to very precise tolerances. Complex machining operations include broaching, crimping, cross-drilling and back/front milling. They offer a strong cost advantage over other methods since automatic coil feeding eliminates bar loading time and produces burr-free cutoffs.

Northwest Swiss-Matic | 8400 89th Ave. North, Suite 490, Minneapolis, MN 55445 | Ph: 763-544-4222